Technology

The Dynamic Q5

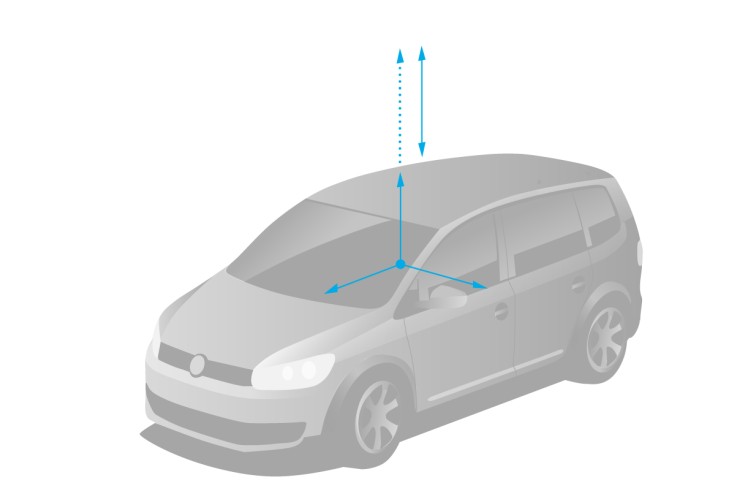

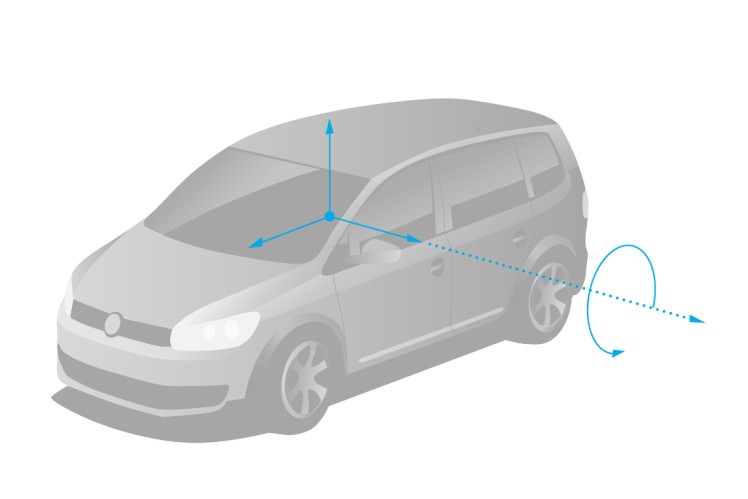

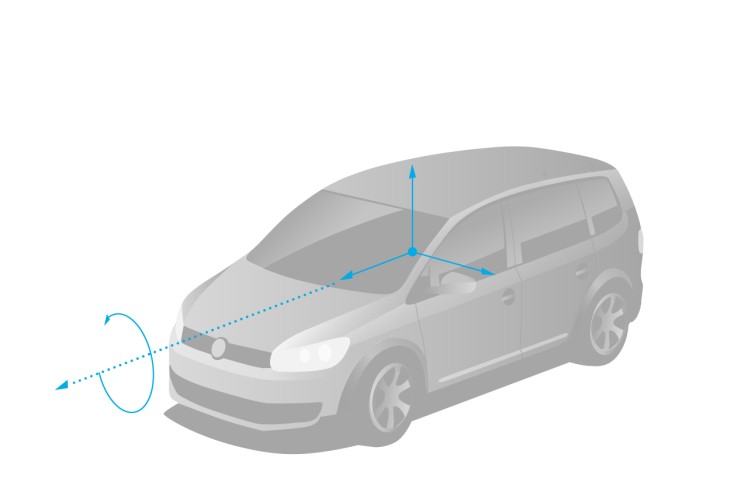

When vehicle dynamics trigger movement, sMOTION kicks in

The evolution of the CDC damping system

The evolution of the CDC damping system

Powerful actuators for a smooth ride

Powerful actuators for a smooth ride

In a nutshell: Thanks to the fully-active sMOTION damping system, driving becomes not only more comfortable but also more dynamic and safer. The challenge: different driving situations each demand a specific damping force. Minimizing body movement in curves requires a high damping force, for example. However, driving over slightly uneven surfaces requires only a little. And maintaining safe contact between the tires and the ground requires a moderate damping force. Used in conjunction with cameras, the chassis system can identify the road conditions by anticipating bumps or potholes, for example, and change its settings accordingly. Thus sMOTION also contributes to highly automated driving.